Introduction

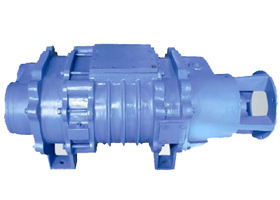

Overview: Gas-cooled Roots pump through both a plum-type rotor, alternating suction and discharge gas to form a vacuum, face outline shape of the rotor includes a lot of curves, such as the cycloid white lines and arcs, lines and arcs, including the rotor and the rotor of the Flat, between the rotor and the cylinder a certain gap, do not touch, smooth rotation, is pumped to the exhaust gas is stable and smooth estuary, the use of a rotor-type three petals, can never be guaranteed and cold-air return inlet port communication port, so that when the pump operates at high pressure differential, the exhaust gas can be cooled by the cooler to cool the return pump rotor in the pump, the vacuum will not affect the ability of the motor via a V-belt or the movable coupling drive pump.

The main structure:

Plum rotor: For the rotor is made of ductile cast by a high-performance, high-precision CNC machining, high precision, the correct type of line design and high-precision machining is the key to ensuring overall performance. Rotor balancing precision experiments.

Synchronous Gear: Gear is one of the most important part of the synchronization Roots vacuum pump, which is used to ensure the synchronization of the two rotors rotate so as to maintain a certain gap between the rotor. Gear surface by high-frequency quenching, and then grinding is made from a special high-precision, low noise.

Bearings: a fixed axis uses double row angular contact ball bearings, telescopic end uses a roller bearing with a high load capacity. These bearings can support high speed and load, to ensure that the gap between the intermediate gear and the rotor.

Seal: Roots pump is bidirectional internal seal with lip seal, can effectively prevent bidirectional flow of each fluid component of fluid consistency. Shaft oil seal using seal.

Dipstick: oil gauge is placed in the front cover. The oil level should be supplied to exceed the level of the center of the oil window. If the oil standard is too low, gears, bearings because of the lack of proper lubricants and damage. So when the pump is not running, be sure to check the height and no contamination with oil, and then re-add oil or replaced with new oil. While rotating the gear oil was thrown from the lubrication of bearings and seals.

More Products